E3NG (ENDER 3 NG)

Take your old, unused Creality Ender 3 and turn it into something amazing—something fast, powerful, precise, and reliable and enjoy the new level of tinkering.

E3NG is a DIY project focused on reviving up to 78%* of parts from your original printer and giving them a brand-new purpose. Many of us started with the simple Ender 3, and it taught us a lot—but 3D printing has evolved, and it’s time to step up. That’s exactly what this conversion is all about.

Originally designed for the Ender 3 Pro, it also supports other models like the V2, Neo, and even the non-Pro variant. The goal? Reuse as much as possible and build a machine that’s significantly faster, more reliable, easy to enclose, and still totally upgradable—because let’s face it, not everyone with an Ender 3 is done tinkering.

Whether you go with a low-budget build or max out performance, you’ll turn your Ender 3 into a CoreXY machine that honors its roots—while bringing it into the Next Generation of printers.

There are two versions to choose from:

- v1.2S (standard) offers a more streamlined, kit-style approach with clear instructions and a straightforward build path—perfect if you prefer to keep things more simple.

- v1.2 (advanced) is for those who like to go deep into the project, tweak every detail, giving you the flexibility to configure your printer to match your own preferences and setup.

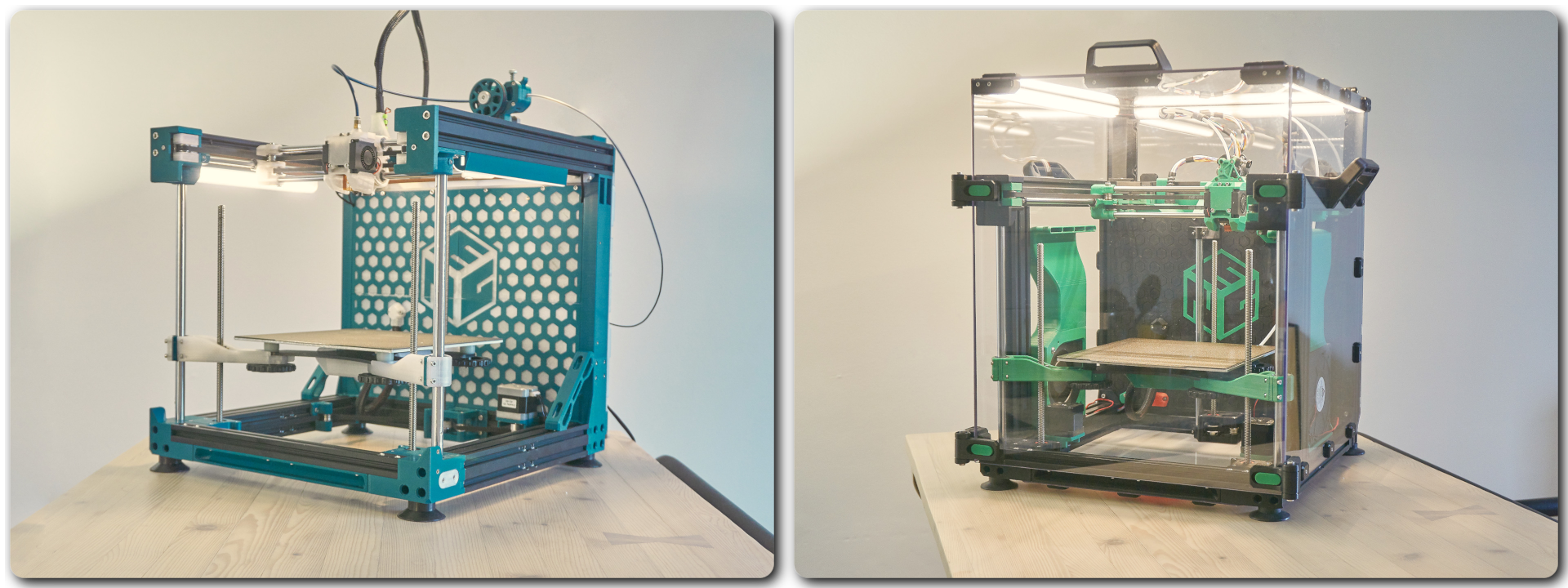

E3NG v1.2S (standard) E3NG v1.2 (advanced)

“NG = NEXT GENERATION”

PRINTER FEATURES

- Build volume (X-Y-Z): 235 x 235 x 245 mm (max Z depends on the hotend used)

- Printer size (X-Y-Z): 407 x 438 x 440 mm ( 455 x 485 x 548 mm enclosed )

- CoreXY motion system

- Linear rods for X, Y and Z axis.

- Stable Z axis with 3 leadscrews and 3 linear rods.

- Enclosed electronics on the back of the printer.

- DIN rails in electronics compartment for easy organization.

- Anti Z wobble system within the bed carriage.

- Easy to enclose.

BONUS FEATURES

- Reuses up to 78%* of the original parts.

- Fanducts optimised with CFD analysis tools.

- Toolhead compatibility with majority of hotends, extruders and bed probes.

- Toolhead with 4 variants of part cooling - dual 4010, dual 4020, dual 5015, CPAP.

- Files designed for easy printability and functionality.

OPTIONAL FEATURES (in the v1.2 - advanced)

- Under bed fan for air circulation and faster chamber heating.

- Active cooling for AB stepper motors.

- Auxiliary fans with 12032 blowers.

- Lasercut metal bed carriage for the best stability.

- Single or triple Z stepper motors.

- and more - see the CONFIGURATION options

continue to:

up to 78% = Measured by weight of the parts from stock Ender 3 Pro. The percentage is calculated when reusing the majority of parts incl. motherboard, screen, screws, hotend (which is all possible). When using the required minimum of parts, 68% is reused.

For extra 9% of part reusage, there are side projects specifically designed to reuse more of the leftover parts - heat set insert press, camera slider (will be released to public later). The number of projects might grow in the future.